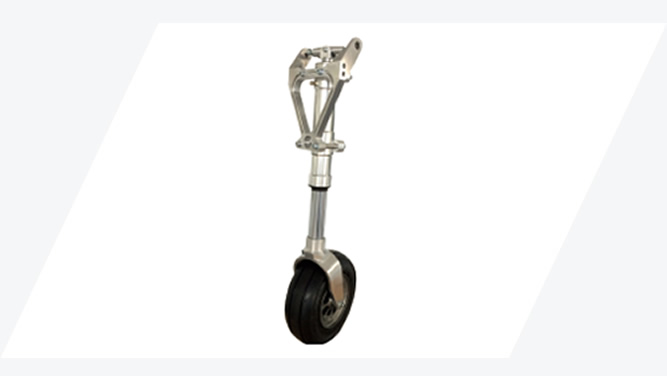

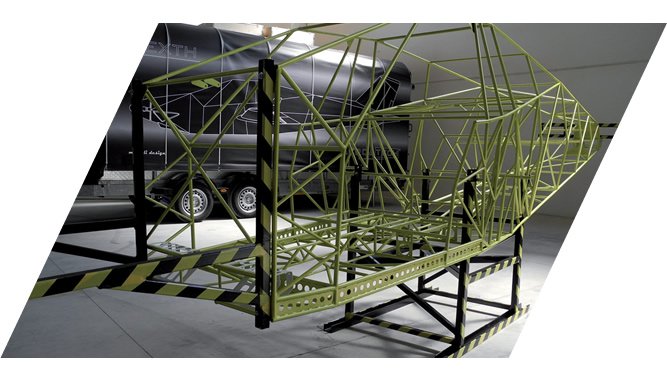

The Metal Concept as a must for real safety

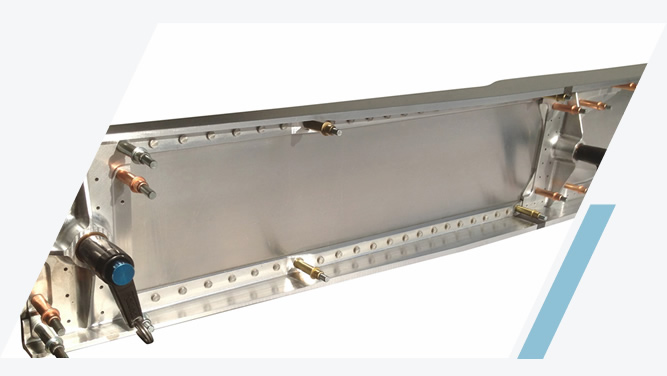

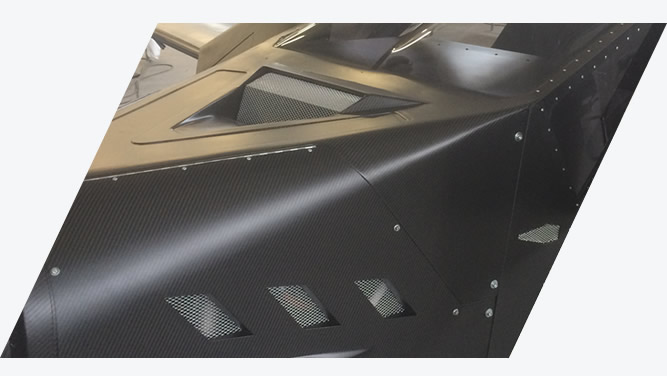

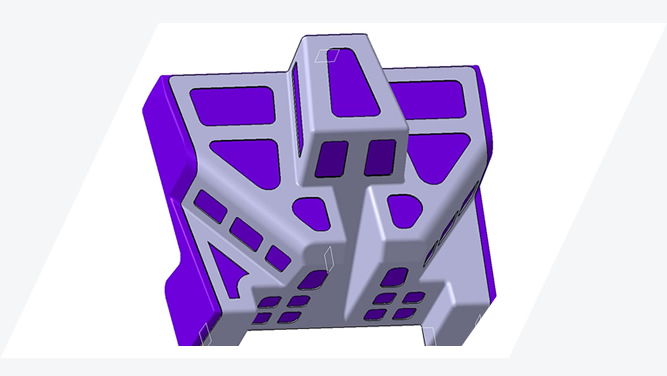

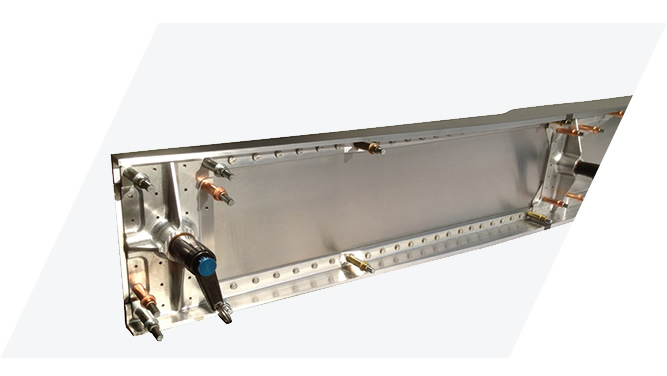

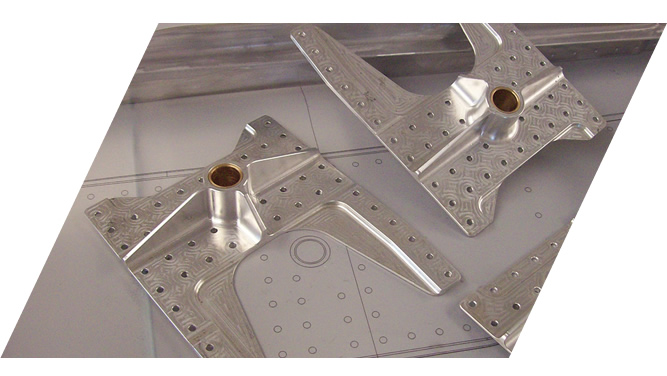

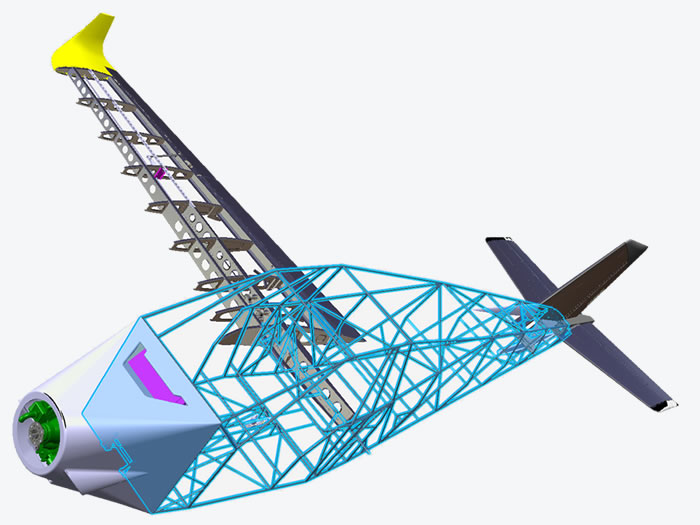

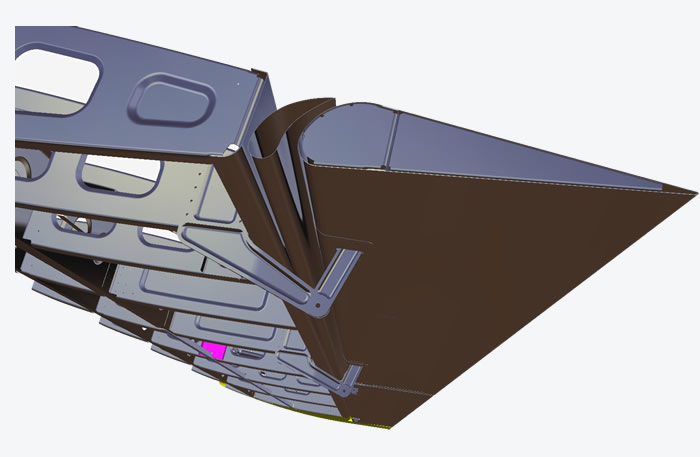

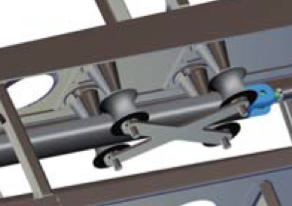

One of the key points of the project is safety, for that the first must for NEXTH design has been to use for the most stressed structural components only aluminum and titanium alloys, and carbon fiber only for aesthetic secondary parts, in order to not compromise any way the capability of the aircraft to fly and land safely whatever happen.